Stac Bond A2

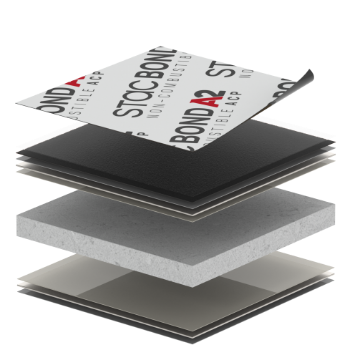

STACBOND® A2 is a non-combustible composite panel made up of two aluminum sheets and a mineral core developed to meet the highest fire classification regulatory requirements.

Thanks to its exceptional mechanical properties: high rigidity, excellent flatness, impact resistance, durability and ease of maintenance together with an A2-s1, d0 reaction to fire classification (according to UNE EN 13501-1:2007), make it the ideal cladding solution for high-rise buildings and high-occupancy buildings.

It complies with the strictest fire classification requirements, among which are:

UNE EN 13501-1:2007 – A2-s1, d0NFPA 285 – PASS

ASTM E84 – CLASS A

DATOS TÉCNICOS

| Physical specifications | UDS. | Value | Standard |

|---|---|---|---|

| Aluminum thickness | mm | 0,5 | |

| Panel thickness | mm | 4 | |

| Panel weight | kg/m2 | 9,8 ± 0,5 | |

| Aluminum alloy | 5005/3005/3105 | UNE EN 573-3 |

| Core Specification A2 | UDS. | Value | Standard |

|---|---|---|---|

| Density | g/cm3 | 2,36 ± 0,1 | |

| Reaction to fire | A2 - S1, d0 | UNE EN 13501-1:2007 |

| General characteristics | UDS. | Value | Standard |

|---|---|---|---|

| Adherence | No loss of adhesion | EN DIN 53151 | |

| Modulus of elasticity (E) | N/mm2 | 70.000 | EN 485-2 |

| Stress at elastic limit (Rp 0.2) | N/mm2 | ≥ 80 | EN 485-2 |

| Stress at break (Rm) | N/mm2 | 125 ≤ Rm ≤ 240 | EN 485-2 |

| Elongation (A50) | % | ≥ 4 | EN 485-2 |

| Impact resistance | 4 Joules/GTØ | EN 13523-5/6 | |

| Chemical resistance | 5% HCI without changes | ISO2812 - METHOD 3 | |

| Use temperature | ºC | -40 / +80 | |

| Acoustic isolation Rw (C;Ctr) | dB | 30 (-1; +3) | ISO 717-1 |

| Country | Standard | Organism |

|

|

|---|---|---|---|---|

| INTERNATIONAL | EPD S-P-01289 |

Tecnalia R&I Guipúzcoa |

|

|

|

|

||

|---|---|---|---|

| Country | Standard | Classification | Classification |

| U.E. | EN 13501-1 | A2-s1, d0 | B-s1, d0 |

| U.E. | NF P 92-501:1995 | · | · |

| POLAND | PN-90/8-02867 | · | NRO |

| EE.UU. | ASTM E84 | CLASS A | CLASS A |

| EE.UU. | NFPA 285 | PASS | PASS |